How does solar power magnification work?

As a consumer, we always strive for getting the best out of our purchases. Things are pretty much the same in solar panels as the consumers want the maximum efficiency out of their solar setup.

For this reason, the solar manufacturing companies are introducing advanced technology in the solar panels manufacturing process.

But is there any other way to increase the production capacity of solar panels? A magnifying glass can make a good case. So let's start our quest and look for answers.

Before jumping into the topic at hand, let me take you back to your childhood. You have a magnifying glass in your hand, and you are about to experiment on paper by concentrating sunlight on it. The super focusing properties of magnifying glass have lit the paper on fire.

The general concept of Mirrors and sunlight

The idea is simple, can we use a magnifying glass to increase our solar production? Yes, we can. The concept of concentrating solar power is an understudy for over a decade now, and scientists are close to making a breakthrough product in the photovoltaic industry.

The use of concentrating mirrors can solve many problems regarding solar installations.

Concentrated Solar Power

So we have only seen concentrating solar power in large thermal power plants. It works on a fundamental principle of focusing the direct sunlight to a receiver that intelligently passes it to some storage.

The heat energy in the storage passes on to the thermodynamic cycle to produce electricity.

There are four ways to install and CSP plant. However, the mirrors cannot be installed directly on the solar panels because the excessive heat may cause them to malfunction or leave them permanently damaged.

- Parabolic trough

- Central receiver

- Dish Stirling

- Linear Fresnel

Parabolic Trough

Parabolic trough systems employ curved mirrors to focus the Sun's energy on a tube that passes through a trough's center. The receiver line absorbs sunlight, achieving 750 °F or more through heat exchangers to heat water and generating vapor, using a highly tempered transmission fluid, such as synthetic oil.

The steam power generates electricity from a conventional steam turbine system. A typical field for solar collectors has hundreds of parallel rows of troughs connected as a series of loops on the north-south axis for the tracks to follow the Sun from East to West. Collector modules are usually 15-20 feet in height and 300-450 feet in length.

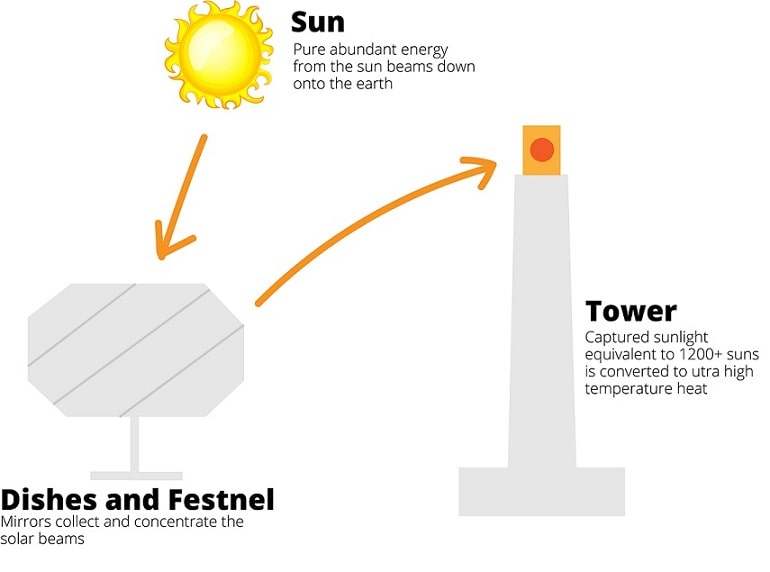

Central Receiver

The power tower systems employ a central receiver system that enables increased operating temperatures and thus increased efficiency.

Computer-controlled mirrors (called heliostats) monitor the Sun on two dimensions and concentrate solar power on a high tower recipient. The concentrating energy is to heat a transmission liquid (above 1000° F) to generate steam and drive a central generator.

Energy storage is readily and effectively integrated with these projects to generate energy 24 hours a day.

Dish Stirling

Mirrors are spread over a parabolic dish surface to concentrate sunlight on a focal receiver. In contrast to previous steam-created CSP technologies, the power generation device uses a working fluid such as hydrogen, heated to 1,200° F in the receiver to power an engine. Each dish revolves across two axes in terms of following the Sun.

Linear Fresnel

CLFR utilizes concepts of curved-mirror trough systems but with extended parallel lines of inexpensive flat slabs of mirrors.

These modular mirror screens focus the energy of the Sun on vertical receivers, consisting of water supply network pipes. The targeted sunlight boils water and creates high-pressure steam for simultaneous use in electricity production and industrial smoke.

Advantages and Disadvantages of Concentrated Sunlight Power production:

Before discussing the pros and cons of Concentrated Sunlight Power production, please note that it is only for the commercial production of electricity.

There is no residential application for Concentrated Sunlight Power production.

Advantages

The CSP technology is best for commercial power production. It is proven fruitful in the long run as compared to other conventional means of power production.

Many European countries are employing CSP as their prime source of electricity production because of its ability to produce hefty 4000 MW of electricity annually.

They are excellent in processing the heat under mean and extremely high temperatures.

Dish Stirling CSP tech is a standalone installation that requires comparatively less than the rest and is efficient for power requirements for a small locality.

They boast incredibly high modularity, efficiency and are also credible for hybrid operations should the need arises.

CSP is an excellent alternative to conventional electricity production. They actively contribute towards lowering the power prices and meeting the global energy requirements.

Their low CO2 emission means less impact on the environment and reducing global warming.

CSP has an immense production capacity and participates conveniently in meeting the power needs.

Disadvantages

CSP technology does have some disadvantages. First and foremost, they are specifically commercially active power production. That is because the installation being costly. And can only be done through proper financing.

The Parabolic Trough has an oil-based heat transfer principle, limiting the efficiency of electricity production in the system. These systems are one-time installations which means they are immovable once installed.

Although their commercial application is comparatively less costly than the rest of the power production applications, the CSP tech is still not readily available globally.

Only a handful of countries use it for commercially meeting the electricity needs. These countries include Spain, the USA, Australia, Germany, and Egypt. Of all these countries, only Spain is utilizing 783 MW annually through CSP.

However, with the tide in its favor, CSP is an emerging market for many countries in GULF, Asia, and North America as an ultimate Electricity production source.

Almost all the CSP systems require installation near the water source. It is because its components need active cooling to perform at maximum capacity.

Installation

A CSP plant requires adequate planning and execution. The geological terrains, heat maps, and water sources are essential aspects of a unique CSP plant.

It starts with a thorough survey and selecting a perfect site for installation by research and development teams, generally the engineers and geological analysts. These men make sure to check all the necessary boxes to determine a proper installation site.

The production unit requires mirrors, mounting structures, receivers, connection pipes, pumps, storage systems, generators, and power blocks.

The construction requires detailed engineering and procurement and a proper utility transport system for the distribution of electricity.

Project finance is the major problem for all utilities, including CSP. It requires proper financing and political stability.

Economic Structure

The CSP installation is usually government-funded as the brag a heft cost of €280 million. It includes site financing, labor cost, equipment pricing, and other expenditures in maintenance and wages.

However, it carries far more benefits both ecologically and competitively. With sound financing and legal support, CSP tech can make way for a safe and secure future investment for decades to come. It is not only cost-effective but also has minimal environmental risk.

Factors that may affect the production capacity

A CSP installation, like any other power production, requires thorough research. Many climate changes may affect the production capacity of a CSP installation. For example, cloudy weather can significantly affect overall production.

Also, the terrain and soil compatibility might come to play its role against the power production. A CSP installation can never work without sound support from legal and political entities. So, it is better to have all the legal requirements checked and approved.

The proper study of heat maps is necessary as it plays a vital role in determining the best possible site for installation. The maintenance of equipment and components is essential to avail the maximum efficiency.

Adjoining tracts of terrain with little cloud cover. A CSP plant runs most efficiently and hence most cost-effectively when built-in capacities of 100 MW and above. While land demands will vary by technology, a typical CSP facility requires 5 to 10 acres of land per MW of power. The wider area facilitates the storage of thermal energy.

Most CSP systems require access to a water source for cooling, much as conventional power plants such as natural gas, coal, and nuclear. Small quantities of water are needed to wash collections and mirror surfaces. CSP facilities might use moist, dry, and hybrid cooling approaches to improve power generation and water retention efficiency.

Solar PV and CSP

Solar PV and CSP are two completely different things. With PV cells composed of semiconductor materials, the photovoltaic (PV) systems convert sunlight directly to energy. Concentrated solar power (CSP) systems utilize sunlight to generate electricity using reflecting equipment such as troughs or mirrors.

As far as energy storage and efficiency are concerned, CSP is superior since it uses TES technology to store energy. However, the PV struggles, as it directly generates electricity to produce or store thermal energy. In addition, power is hard to store

A recent breakthrough study has led the scientist to unveil the use of smaller-scale CSP to manufacture solar PV panels. The study says the use of CSP can actively contribute to PVs' production capacity by thousand times. CSP-powered solar PV might get into the market sooner rather than later.

So far, there isn't any product of sort in the market, but we might be able to see such products soon.

Given the enhanced efficiency of CSP, its introduction into the PV industry is imminent. However, there are some concerns regarding the crossover between CSP and PV.

One of them is heat, as the CSP generated a great deal of heat while it is near harmful for silicon cells in PV and the equipment nearby. Scientists are working tirelessly to find a solution for this issue and introduce CSP-powered PV panels in the market.

On a residential level, solar PV is still a common alternative. We have devised a little comparison for you to understand the difference clearly.

| PV | CSP |

| Less sensitive to dust | Very sensitive to dust |

| Easy installation, | Complex installation |

| Residential, Commercial | Commercial |

| No specific land requirement | Flat topography |

| Built-in Cooling system | Excessively require water |

| Low, medium voltage | Medium-high voltage |

| Near the grid | Far from grid |

| Low cost | Higher cost |

| Less number of equipment | The high number of equipment |

| Low maintenance | Skilled maintenance |

| Simple and movable | Complex and fixed |

| Readily manufactured | Manufactured on demand |

| Distributed power generation | Centralized power generation |

| Less electricity loss | Electricity loss on distribution lines |

Conclusion

The unhinged potential of CSP is undeniable. Many countries are currently pouncing on the opportunity to meet their energy requirements. CSP-based electricity-producing plants are a step closer to eradicate the global power crisis and stabilizing, even lowering the ever-rising electricity prices.

The production capacity of CSP is more efficient and convenient than the electricity produced through biomass, coal, oil grids, etc. It has minimal environmental hazards, which means it participates actively in global clean energy initiatives.

Productivity for the majority of CSP technology is between 7 and 25 percent. Wind turbines can achieve up to 59% efficiency. In comparison, hydropower systems may reach an efficiency of up to 90% compared to energy conversion efficiencies from other renewable energy technology.

Solar thermal power plants are a credible economic choice to supply a considerable proportion of global energy demand in many nations. CSP has tremendous room for improvement, particularly in the regions with significant solar irradiation.

Although current energy costs generated by Concentrated Solar Power stations remain high, a tangible medium to long-term cost reduction potential exists.

Considerable revenue is already being invested in the development of innovations and breakthroughs to reduce costs significantly. Business opportunities shall rise once specific expenses decrease.