Compact Linear Fresnel Reflectors

Photovoltaic cells are typically used in solar systems to convert solar energy directly into electrical energy. Another method of utilizing solar energy is to use sunlight to convert it into thermal energy via some solar collecting process.

Solar collectors are classified into two types: concentrating collectors and non-concentrating collectors. Non-concentrating solar collectors are used for small applications such as domestic hot water heating.

While concentrating solar collectors are used in large applications such as the generation of thermal power with high efficiencies at variable temperatures.

There are additional techniques or types of concentrating solar collectors available. Solar Towe Concentrator (STC), Parabolic Trough Concentrator (PTC), Linear Fresnel Reflector (LFR), and Parabolic Dish are examples.

The most expensive and complex manufacturing design is the Parabolic Trough Concentrator (PTC), but it is the most widely used technique. When compared to the Parabolic Trough Concentrator, the Linear Fresnel Reflector (LFR) is a much simpler design with a lower cost (PTC).

It is also very efficient in terms of land usage. As a result, it has been considered a better choice most of the time when there is limited land available.

What is Compact Linear Fresnel Reflector (CLFR)?

Compact Linear Fresnel Reflector (CLFR) is a type of Linear Fresnel Reflector Solar System (LFR). Linear Fresnel Reflector (LFR) is a technique that uses reflectors (mirrors) to focus sunlight into a single receiver.

It employs, as the name “Linear” implies, a series of linear solar mirrors (not in a parabolic shape, which is more expensive than linear shape mirror).

We can improve the efficiency of the solar power system by increasing the amount of heat, which increases the rate of energy conversion.

How does CLFR work?

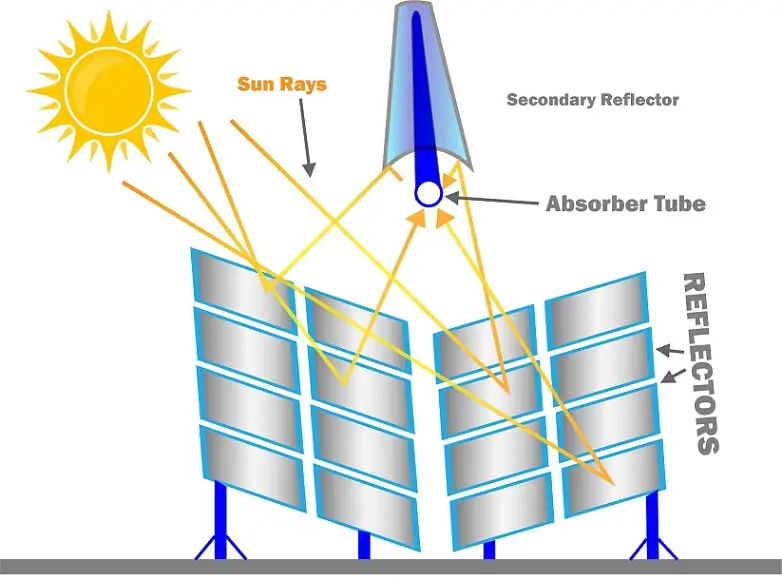

Compact Linear Fresnel Reflector system consists of a series of flat (or small curvature) mirrors that direct sunlight onto one of the receivers (standing on the tower above the mirrors).

One of the mirrors (shaped as a curvature) could also be installed on the top of the receiver to improve light focus.

As the sun moves throughout the day, the mirrors are aimed accordingly to obtain a perfect reflection. The aiming is done through computer control.

When compared to the Trough and dish concepts, it is much more cost effective to use only one or two receivers for several mirrors while the process is the same, such as following simple one-line focus geometry with one axis for tracking.

However, the Linear Fresnel Reflector has a Compact Linear Fresnel Reflector system that uses a series of flat (or small curvature) mirrors to focus the direct sunlight onto one of the receivers (standing on the tower above the mirrors).

However, the Linear Fresnel Reflector has a Compact Linear Fresnel Reflector system, which uses a series of flat (or small curvature) mirrors to focus the direct light of the sun onto one of the stationary receivers (standing on the tower above the mirrors) and does not require fluid couplings.

Furthermore, the receiver does not require the support of the mirrors, making it more structurally simple. The best representation of a Linear Fresnel Reflector is shown in Figure 1.

Let's look at how power flows; a CLFR or LFR is simply a method of collecting solar power (solar power collector). The Linear Fresnel Reflector works on the principle that flat mirrors are connected in series to collect solar energy and focus it on a receiver (positioned above the mirrors).

The solar power is then used by the receiver to generate steam power, which is used to drive the turbine.

Electrical energy is generated by the turbine. The advantage of this technique is that steam is generated directly from the sun without the use of any other heat transfer methods such as fluids or other processes.

In other words, no heat exchange occurs in order to produce steam (sun heat directly boils the water present in the receiver).

History

The linear Fresnel reflector technique was first used in a solar electric system in 1961. It was created in Italy by Giovanni Francia (University of Genoa). He conducts an experiment in which he raises the temperature of an object using the Linear Fresnel Reflector Technique.

During the 1973 oil crisis, FMC Corporation and other companies observed the Linear Fresnel Reflector. However, CLFR was developed for real-time use for the first time in 1993.

The advanced absorber was introduced in 1999, which furthered research. In 2010, a non-imaging optics technique was introduced for further advancement, allowing for higher concentration and acceptance angle in CLFR for maximum sunlight utilization.

The Linear Fresnel Reflector (LFR) Technique is based on Augustin-Jean Fresnel's invention of the Fresnel lens effect (French Physicist). The Fresnel Reflector Design allows for the creation of a lens with a large aperture and a short focal length without the need for mass and volume of material.

It is less expensive than parabolic reflectors, which are more expensive. One significant disadvantage of this design is the shading effect of adjacent mirrors, which can only be achieved by utilizing more ground space, which raises costs.

Difference between the CLFR and LFR

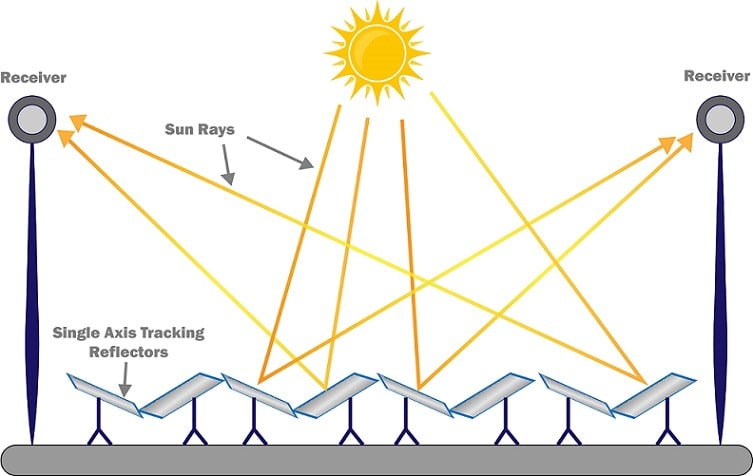

The Compact Linear Fresnel Reflector (CLFR) is a type of advanced Linear Fresnel Reflector (LFR). It also provides a solution to the field problem associated with the Linear Fresnel Reflector (LFR).

Because the LFR has only one linear absorber for all of the mirrors to focus on, the reflector selection for orientation or focus is limited (reflector only has one receiver to focus).

This may be suitable for a small size field, but if the field is large and the system must provide electricity to the mega load class, two linear absorbers for the reflectors are more appropriate.

The absorbers are placed near the reflectors so that the reflectors can choose to focus the sunlight's radiation onto either of the absorbers (receivers).

In comparison to LFR, the additional absorber in CFLR allows the reflectors to produce more densely packed arrays.

This is because patterns of changing reflector inclination could allow the closely packed reflectors to be positioned without blocking and shading. Figure 2 depicts a representation of the CLFR.

The beam blocking in LFR occurred between the mirrors of two adjacent reflectors. In the case of CLFR, beam blocking is minimized, and higher reflector densities are permitted.

The heights of the absorber or receiver tower are also reduced. Although height is not a major issue when the land area is large. These are some of the advantages of the Compact Linear Fresnel reflector (CLFR) over the traditional LFR.

Main Parts of CLFR Design

The Reflector (also known as mirrors) and Absorber (also known as receiver) are the main parts when we look at the design picture of the CLFR.

Reflector:

Reflectors are mirrors that are arranged in a row just above ground level. The reflectors must direct the sun's rays to the receiver or absorber.

The advantage of Linear Fersenal Reflectors over other types of concentrating solar systems is that they have Fresnel reflectors. Fresnel Reflectors are based on the Fresnel lens effect.

The Fresnel lens effect allows for the creation of a mirror with a large aperture and a short focal length without reducing the volume of the required material for the reflector.

The use of the Fresnel effect for reflectors saves money because parabolic reflectors are expensive. However, thanks to the invention of nanotechnology, it is now less expensive to construct parabolic reflectors. Figure 3 depicts a series of reflectors.

The progress of the incident rays throughout the day is usually a problem with this LFR system. Even when the sun moves in a different direction, the reflectors stay in the same spot all day.

So, in order to keep the reflectors following the sun's rays, the CLFR technique has the reflectors aligned in a north-south orientation and turning at one axis. This is accomplished by using computer programming to control the reflectors via a solar tracking system.

Using this technique, the angle of incidence between the reflectors and the sun rays can be kept perfect, allowing maximum energy to be harvested.

Receiver or absorbers

The receivers or absorbers are located at the focal point of the reflectors or mirrors and are mounted on the top of a tower. It must be close to the reflectors in order to collect the sun's radiation. Its secondary function is to heat the water and turn it into steam.

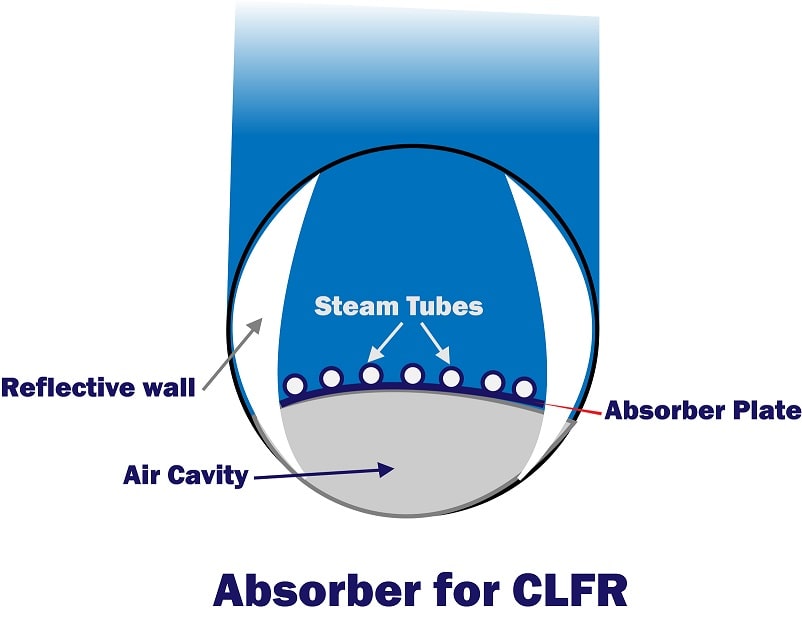

An absorber's most basic design consists of a glass tube for the steam and an inverted air cavity for the flow of sun rays.

The steam in the glass tube should interact with the sun rays collected by the reflectors. The design's simplicity also makes it less expensive. While designing the absorbers, the following factors must be considered:

The design should be optimized so that the transfer heat between the fluid and the absorber is as high as possible, with no energy loss.

However, this is also dependent on factors such as the material used to construct the steam tubes.

The tubes should be optimized to produce the most heat emission for the heat absorbed from the outside of the tubes. The acceptable surface ratio is that the tube emits only 7% of infrared radiation while absorbing 96% of heat from incident rays.

Another consideration is that the temperature distribution across all surfaces of the absorber should be linear. Otherwise, the non-uniform temperature distribution will cause surface degradation.

By varying the thickness of the insulation, the size of the absorber's aperture, and the depth of the absorber, the absorber could be made perfect for temperature distribution uniformity.

So, while designing a concentrating solar power system, these factors should be kept in mind; while there are many other important considerations, only the most important ones are discussed here. The CFLR absorber is shown in Figure 4 below.

Advantages & disadvantages of CLFR

Let us take a look at the advantages and disadvantages of using CLFR technology over other types of concentrating solar systems (parabolic trough and dish, power solar tower, and dish engine system).

Advantages

As previously stated, the greatest advantage of CLFR over other systems is that they have linear or flat shape mirrors (Reflectors) that save a significant amount of money when compared to parabolically shaped reflectors. Curvature is the shape of mirrors in the parabolic trough and dish system (parabolic shape).

The CLFR's absorber or receiver structure is much simpler than that of other types of concentrating solar systems. This has an impact on the cost of design as well.

The reflectors and absorbers in a Compact Linear Fresnel Reflector (CLFR) are not connected or require each other's support, making the design of a CLFR simpler than that of other techniques such as a parabolic trough and dish system.

Because of the CLFR's simplicity of operation, the power system could be hybridized by combining another source of electricity generation (such as fossil fuel) in the event that the sun is obscured by clouds.

Another advantage of using concentrating solar power is that water can be used as a fluid for heat transfer, eliminating the need for pumping and flow control. Furthermore, the system's simplicity makes maintenance easier.

This system requires a small amount of land or space. As a result, a small area is required to implement the CLFR.

Disadvantages

Although there are numerous advantages to using LFR or CLFR over other systems, there is a significant disadvantage.

When compared to the Parabolic trough and dish solar power system, the CLFR's efficiency in converting sun rays into electricity is not as high. However, it can be used effectively for power purposes.

While the problem of shading and beam blocking occurs in LFR, forcing the space between the reflectors to be increased, thus increasing the cost. It does not occur in CLFR due to the multiple absorbers.